LEARNING RESOURCES

Articles on our products, brewing beer, and starting your own brewery.

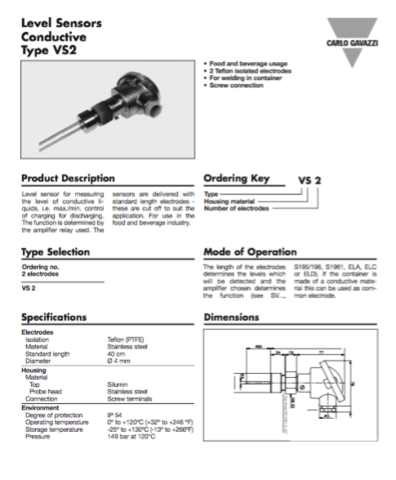

Colander Water Level Controller Spec Sheet

The BREWHA Colander Water Level Sensor provides automatic control of the pump when recirculating wort during mash. If the wort level drops below the end of the probes, the pump will...

Colander Water Level Controller Spec Sheet

The BREWHA Colander Water Level Sensor provides automatic control of the pump when recirculating wort during mash. If the wort level drops below the end of the probes, the pump will shut off, helping lower the risk of dry-firing the elements, and creating high pressure differential in the Colander that will lead to a stuck mash. The Sensor should be hung from the top of the Colander, and a tight connection made as the Colander provides the grounding for the sensor and will not otherwise function.

Troubleshooting the March TE-5S-MD pump

If your pump is not pumping liquid, check the following things: Ensure the correct power is available to the pump (120 or 240V). The larger TE pump has an auto...

Troubleshooting the March TE-5S-MD pump

If your pump is not pumping liquid, check the following things: Ensure the correct power is available to the pump (120 or 240V). The larger TE pump has an auto shut off if it is overheated. It should not get overheated under normal operation and...

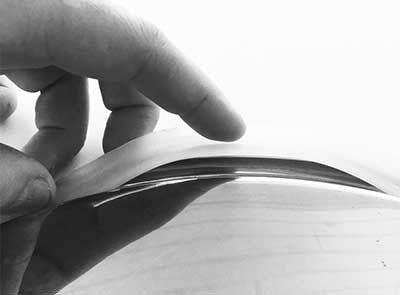

How to Clean and Sanitize a Beer Transfer Hose

When racking beer, one primary source of infection can be the transfer hose that is used. Hoses can easily develop knicks and cracks internally that are hard to spot, harbor...

How to Clean and Sanitize a Beer Transfer Hose

When racking beer, one primary source of infection can be the transfer hose that is used. Hoses can easily develop knicks and cracks internally that are hard to spot, harbor bacteria and are very hard to effectively sanitize with chemicals. Chemical cleaners wash over the surface but don’t effectively deal with...

Water Flow Meter Spec Sheet

This accurate and reliable Flow Meter is useful for metering the amount of water going into your brew system. It can be particularly useful when adding sparge water to add the...

Water Flow Meter Spec Sheet

This accurate and reliable Flow Meter is useful for metering the amount of water going into your brew system. It can be particularly useful when adding sparge water to add the precise amount needed to hit your pre-boil target. It is recommended to install it at a horizontal orientation and...

Preventing Leaks and Galling in the 4-in-1 Ferm...

The 4-in-1 fermenter lid is held in place with eye bolts. Eye bolts are used over standard nuts as they are easier to open with fingers—no tools are necessary. However, when...

Preventing Leaks and Galling in the 4-in-1 Fermenter

The 4-in-1 fermenter lid is held in place with eye bolts. Eye bolts are used over standard nuts as they are easier to open with fingers—no tools are necessary. However, when higher pressure is being applied to the vessel (up to 14.9psi), a tool is likely needed to tighten the lid down so it doesn't leak. For a tighter seal, a screw driver (or other steel bar) can be used to tighten the ring by...

Great Technique for Improving Mash Efficiency

During the mash, enzymes attack complex carbohydrates in the grain and break them up into more simple sugars that yeast can digest. If all (or most) of the available complex carbohydrates...

Great Technique for Improving Mash Efficiency

During the mash, enzymes attack complex carbohydrates in the grain and break them up into more simple sugars that yeast can digest. If all (or most) of the available complex carbohydrates are modified by the enzymes and extracted in the wort, a 'high efficiency' is achieved. If much of the total available carbohydrates remain in the grain and...

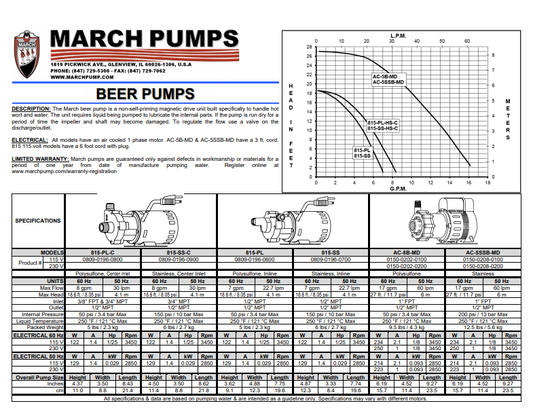

March 815 and March TE-7S-MD Spec Sheet

The March 815 and TE-5S-MD are American made, UL certified (CSA approved) commercial grade, high-performance pumps that will give years and years of service. Read the full product spec sheet here.

March 815 and March TE-7S-MD Spec Sheet

The March 815 and TE-5S-MD are American made, UL certified (CSA approved) commercial grade, high-performance pumps that will give years and years of service. Read the full product spec sheet here.

Sparging with the BIAC

While not absolutely necessary, some brewers prefer to rinse or 'sparge' their grain at the end of the mash period to recover as much sugar as possible. While cold water can...

Sparging with the BIAC

While not absolutely necessary, some brewers prefer to rinse or 'sparge' their grain at the end of the mash period to recover as much sugar as possible. While cold water can be used, it is generally recommended to use hot water at 75°C/167°F as sugars will be recovered more readily and the grain bed kept more fluid, allowing easier...

Installing the fermenter lid gasket

All models of the BREWHA 3-in-1 fermenter have a silicone lid gasket for sealing the lid and providing up to 3psi of pressure for racking beer into kegs. If the lid...

Installing the fermenter lid gasket

All models of the BREWHA 3-in-1 fermenter have a silicone lid gasket for sealing the lid and providing up to 3psi of pressure for racking beer into kegs. If the lid is kept clean, the lid gasket can generally be kept in place as it can be sanitized simple by putting into position...

Preventing Scorched Wort and Burnt Flavor in Yo...

After four weeks of eager anticipation, there are few things more devastating to a brewer than discovering an unwanted microbial infection or tasting burnt/smokey notes in your latest brew. The BIAC...

Preventing Scorched Wort and Burnt Flavor in Your Beer

After four weeks of eager anticipation, there are few things more devastating to a brewer than discovering an unwanted microbial infection or tasting burnt/smokey notes in your latest brew. The BIAC takes you a long way towards preventing the unwanted infection, since by boiling in the fermenter it is heat sanitized. However, one needs to be careful...

Heating and Chilling Methods for the 5BBL BIAC

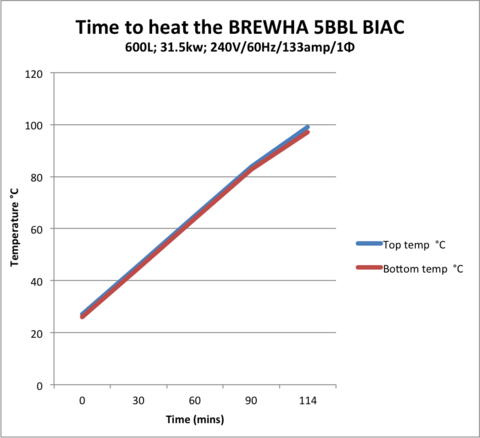

There has been some discussion online about the benefit of circulating wort inside the BIAC fermenter during chilling to reduce the chill time so we put it to the test in...

Heating and Chilling Methods for the 5BBL BIAC

There has been some discussion online about the benefit of circulating wort inside the BIAC fermenter during chilling to reduce the chill time so we put it to the test in our largest system, the 5BBL BIAC. We tested on the 5BBL, since being the largest system we currently offer, it has the lowest chilling surface area to wort ratio and therefore (all other factors being equal) the longest chill time of the BIAC systems.

Controlling Vorlauf and Lauter Rates to Prevent...

Not long ago Dave Miller sent me a link to an article he wrote on vorlauf and lautering that has really helped with questions around increasing lauter rates and preventing stuck mashes. In...

Controlling Vorlauf and Lauter Rates to Prevent a Stuck Mash

Not long ago Dave Miller sent me a link to an article he wrote on vorlauf and lautering that has really helped with questions around increasing lauter rates and preventing stuck mashes. In his article he states that most people lauter (and vorlauf) too fast and while there are many possible causes, the major culprit...

Assembling the Water Pressure Regulator

Every hose and tank is designed with a maximum allowable working pressure (MAWP), which if exceeded, will cause damage and could even pose a safety hazard. The BREWHA tank jackets...

Assembling the Water Pressure Regulator

Every hose and tank is designed with a maximum allowable working pressure (MAWP), which if exceeded, will cause damage and could even pose a safety hazard. The BREWHA tank jackets have been designed to hold up to 5psi of pressure (7psi in the MB 4-in-1s) which is more than enough pressure to...

Installing Your BIAC Complete All-in-One Brewery

In this video we will be looking at how to setup the BREWHA BIAC. While today we are setting up a 5 barrel BIAC, most of the features and fittings...

Installing Your BIAC Complete All-in-One Brewery

In this video we will be looking at how to setup the BREWHA BIAC. While today we are setting up a 5 barrel BIAC, most of the features and fittings are also found on the smaller models. The first thing to set up is the hoist. On the larger models of the BREWHA BIAC, an overhead hoist is necessary to raise the Colander, and...

Brewing With Fresh Hops All Year Long

Brewing with fresh hops has long intrigued me. It is fairly intuitive that fresh hops would have different flavors than dried hops, and being able to grow a key ingredient for...

Brewing With Fresh Hops All Year Long

Brewing with fresh hops has long intrigued me. It is fairly intuitive that fresh hops would have different flavors than dried hops, and being able to grow a key ingredient for your brew has a certain appeal. And, I happen to live in a great spot for it as Vancouver has a good climate for growing hops; hops can be seen in the back yards of many homes around the city wild patches can even be found growing around the city...

How To Enter a Beer Brewing Competition

(This article was submitted by Ken Noesgaard of Saskatoon, SK. He documents his experience with brewing beer in the BIAC and the steps involved in entering a brewing competition.) I have been...

How To Enter a Beer Brewing Competition

(This article was submitted by Ken Noesgaard of Saskatoon, SK. He documents his experience with brewing beer in the BIAC and the steps involved in entering a brewing competition.) I have been brewing beer since 1985 and all-grain brewing since 1999. Before deciding on my BREWHA BIAC I was mashing in a 10 gallon Gott cooler with a false bottom and boiling in a 20 gallon...

Small Footprint, Big Flavor

The Vancouver Sun published an article today on the BREWHA BIAC. Read the full story here.

Small Footprint, Big Flavor

The Vancouver Sun published an article today on the BREWHA BIAC. Read the full story here.

Unloading Spent Grain

Unloading grain from the BREWHA Mash Colander is quick and easy with an overhead hoist. The BREWHA BIAC is the simplest, most intuitive and user-friendly brewing system available.

Unloading Spent Grain

Unloading grain from the BREWHA Mash Colander is quick and easy with an overhead hoist. The BREWHA BIAC is the simplest, most intuitive and user-friendly brewing system available.

Disassembling the BREWHA Sanitary Ball Valve

Completely disassembling a valve to remove any sediment that is trapped inside is essential sanitary technique for any brewery. The BREWHA Sanitary Valve is the simplest and easiest valve you’ll...

Disassembling the BREWHA Sanitary Ball Valve

Completely disassembling a valve to remove any sediment that is trapped inside is essential sanitary technique for any brewery. The BREWHA Sanitary Valve is the simplest and easiest valve you’ll ever disassemble. Aside from the very first time (when a wrench may be needed to loosen the nut on the handle) no tools other than your fingers are required to disassemble the valve. Disassembly, cleaning and reassembly can all happen inside a minute...

How to Quickly Transfer Beer from Your Fermente...

While BREWHA's Fermentor to Keg Racking Hose allows a brewer to easily transfer beer to a keg in an oxygen free environment using the 'beer out' post of the keg, the...

How to Quickly Transfer Beer from Your Fermenter to a Keg

While BREWHA's Fermentor to Keg Racking Hose allows a brewer to easily transfer beer to a keg in an oxygen free environment using the 'beer out' post of the keg, the 'beer out' post on most kegs is through a 1/4" tube which can restrict beer flow and be somewhat time consuming. This article describes an easy method for rapid racking of beer to a keg using a larger diameter hose.

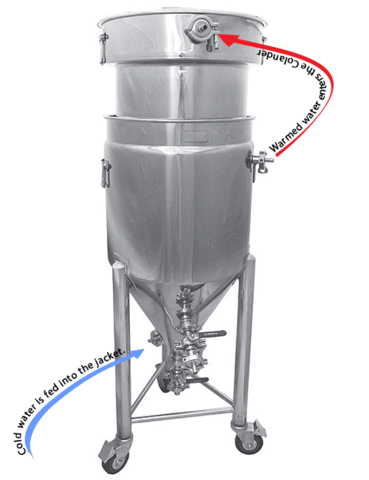

Overview of the Water, Beer and Wort Chiller

This video describes how to install and use the BREWHA Water, Beer and Wort Chiller to chill wort after boiling is complete, maintain fermentation temperature when making beer, (including lagering...

Overview of the Water, Beer and Wort Chiller

This video describes how to install and use the BREWHA Water, Beer and Wort Chiller to chill wort after boiling is complete, maintain fermentation temperature when making beer, (including lagering beer) and chill beer on its way from the keg to tap.

How to Install and Program the ETC Digital Temp...

The ETC120, exclusively made for BREWHA, is a cost-effective and fully functioning temperature monitoring and controlling device. The temperature probe is inserted in one of the BREWHA vessels for tracking...

How to Install and Program the ETC Digital Temperature Controller

The ETC120, exclusively made for BREWHA, is a cost-effective and fully functioning temperature monitoring and controlling device. The temperature probe is inserted in one of the BREWHA vessels for tracking temperature, and the heating and cooling receptacles allow for operating the Heating Element and Temperature Control Valve as needed. This manual provides instructions for installation and maintenance of the ETC120.

Instruction Manual for the BREWHA Water, Beer a...

The Lindr water chillers are 120V chillers that can be multi-purposed for many tasks; it is the perfect companion for the serious home brewer, or small commercial applications. This manual provides the...

Instruction Manual for the BREWHA Water, Beer and Wort Chiller

The Lindr water chillers are 120V chillers that can be multi-purposed for many tasks; it is the perfect companion for the serious home brewer, or small commercial applications. This manual provides the instructions necessary for setup and operation of the chiller.

Brewing Beer with the BREWHA BIAC

This video provides a detailed overview on how to brew beer with the BREWHA BIAC. Detailed step by step instructions provide new and experienced brewers alike with fun and engaging...

Brewing Beer with the BREWHA BIAC

This video provides a detailed overview on how to brew beer with the BREWHA BIAC. Detailed step by step instructions provide new and experienced brewers alike with fun and engaging information that will give them confidence in brewing with the BIAC and have them brewing like a professional in no time at all.