Controlling Vorlauf and Lauter Rates to Prevent a Stuck Mash

Although it was published a couple years ago, I just recently read Dave Miller’s ‘Brew Like a Pro’. Dave was the brewer at Blackstone Pub (Nashville, TN) for many years and while the focus of this book is on brewing at home, it is heavily imbued with experiences and anecdotes drawn from his career in the brew pub. While some online have been critical of the content on pub experiences (suggesting it was not a book for homebrewers) I found it fascinating as many of the brewing challenges encountered at a commercial scale are also encountered when home brewing, and, to be honest, I’m one of those brewers who wants to ‘brew like a pro’ so I find pro experiences deeply interesting.

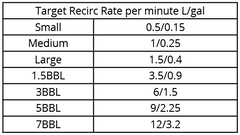

One of the most helpful things I have (relatively recently) gleaned from Dave Miller’s writings, however, came not from this book but from his website articles. Not long ago he sent me a link to an article he wrote on vorlauf and lautering that has really helped with questions around increasing lauter rates and preventing stuck mashes. In his article he states that most people lauter (and vorlauf) too fast and while there are many possible causes, the major culprit in a stuck mash is adding water too quickly, leading to a build up of pressure in the mash tun (Mash Colander for BREWHA brewers) and reduction of pressure under the Mash Colander. If the wort is being returned (or water added) too quickly to the Mash Colander, it needs to be throttled by partially closing the valve on the wort return or sparge line (a valve should always be positioned downstream, not upstream, of the pump). The higher pressure inside the Mash Colander forces the grain down, compressing it against the false bottom and causing it to prevent water/wort from flowing through. He said that there is a general rule in brewing that the pressure differential should not exceed more than 6” worth of pressure drop on a water column, and only 2-3” is preferred.

For BREWHA customers, this means that the water in the fermenter surrounding the Mash Colander should never be more than 6” lower (and 2-3” is desired) than the water level inside the Mash Colander or the higher water level in the Colander will compress the grain bed too much and will impede flow. As the difference approaches 6”, the pump return or sparge water flow rate needs to be throttled back until the difference is reduced to the appropriate level. If monitoring the difference from inside the Mash Colander during vorlauf, since the water volume around the Mash Colander is much less than the water volume inside the Mash Colander (so the water level change moves more slowly), a 6” drop around the Colander means that the water level inside the Mash Colander should be kept from rising more than ~0.5” from the level at which you first started mashing. If it exceeds this you could have problems with compaction in the grain bed (not to mention at some point risking exposing the heating element if the so much liquid is withdrawn from underneath the Colander that the water level drops that far).

For BREWHA customers, this means that the water in the fermenter surrounding the Mash Colander should never be more than 6” lower (and 2-3” is desired) than the water level inside the Mash Colander or the higher water level in the Colander will compress the grain bed too much and will impede flow. As the difference approaches 6”, the pump return or sparge water flow rate needs to be throttled back until the difference is reduced to the appropriate level. If monitoring the difference from inside the Mash Colander during vorlauf, since the water volume around the Mash Colander is much less than the water volume inside the Mash Colander (so the water level change moves more slowly), a 6” drop around the Colander means that the water level inside the Mash Colander should be kept from rising more than ~0.5” from the level at which you first started mashing. If it exceeds this you could have problems with compaction in the grain bed (not to mention at some point risking exposing the heating element if the so much liquid is withdrawn from underneath the Colander that the water level drops that far).

There are a several ways BREWHA customers can monitor the pump recirculation during vorlauf and water addition during lauter to ensure a pressure differential (water level difference) does not exceed the recommended amount.

First, a water level ruler can be moved inside the Colander and any level changes observed; by recording the level once mashed in, any rise inside the Colander, means a drop in pressure under the Colander as liquid is displaced from under the Colander into the Colander.

Second, a transparent hose can be connected to one of the unused ports at the bottom of the fermenter, and attached to the top of the fermenter (securely so it won’t fall and drain wort onto your floor). The hose will fill with wort to the level of the wort inside the fermenter so it gives an easy visual of what is happening under the Colander; by comparing it to the wort level inside the Colander the pressure difference can be ascertained (the wort level in the hose should be within six inches of the level inside the Colander).

Third, electric water level sensors are commercially available online (one is included with the 1.5BBL 2HL complete brewing system, 3BBL 3HL complete brewing system, 5BBL 6HL complete brewing system and 7BBL 8HL complete brewing system BIAC packages) that could be used to turn a pump off if the water drops too much in the fermenter (or rises too much inside the Mash Colander). These solutions are more expensive than the above suggestions, but are more ‘automated’ so a brewer can have a higher degree of confidence the flow rates won’t get out of hand (a valve should still be used to throttle flow rate to as close to target as possible, and the level sensor only used as safety backup, the sensor should not be used as the primary means of flow control).

It is also a good idea to keep the Power Box output set to ~30% while mashing as this reduces the likelihood of scorched flavors in the wort or even dry-firing (melting) the heating element if temporarily exposed.

Preventing a stuck mash and ruining the electric heating element

Increasing mash efficiency