Articles on brewing equipment, how to brew beer and open a brewery

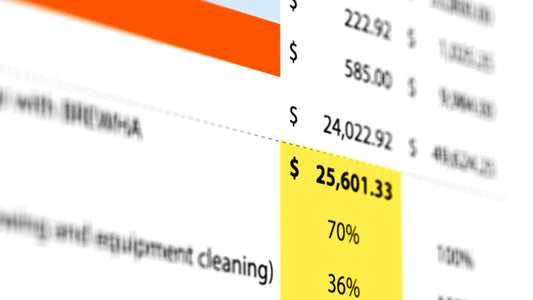

Brewery Startup Cost Calculator

Are you dreaming of starting your own brewery? This small brewery startup budget calculator is meant to provide you with a guideline for first year costs when starting your small...

Brewery Startup Cost Calculator

Are you dreaming of starting your own brewery? This small brewery startup budget calculator is meant to provide you with a guideline for first year costs when starting your small...

Homemade Root Beer

The Homemade Root Beer Sarsaparilla we are brewing today will be in the smallest of the BREWHA brewing systems, but the steps we use can be copied with all 8...

Homemade Root Beer

The Homemade Root Beer Sarsaparilla we are brewing today will be in the smallest of the BREWHA brewing systems, but the steps we use can be copied with all 8...

How to Make Beer (Video)

In this video we demonstrate how to make delicious craft beer in 12 steps using the BREWHA BIAC beer brewing system.

How to Make Beer (Video)

In this video we demonstrate how to make delicious craft beer in 12 steps using the BREWHA BIAC beer brewing system.

Key Criteria for Brewery Success

Starting a business is not easy, and statistics indicate that four out of ten business startups fail by year five. With the market for new microbrewery and tap rooms going strong, the probability of success might be higher...

Key Criteria for Brewery Success

Starting a business is not easy, and statistics indicate that four out of ten business startups fail by year five. With the market for new microbrewery and tap rooms going strong, the probability of success might be higher...

How to Open a Brewery and Serve the Freshest Beer

How to open a brewery, and serve the freshest beer? Randy of James Calley Brewing Company Tulsa, Oklahoma tells us how. They have a large, open-concept brewery and are...

How to Open a Brewery and Serve the Freshest Beer

How to open a brewery, and serve the freshest beer? Randy of James Calley Brewing Company Tulsa, Oklahoma tells us how. They have a large, open-concept brewery and are...

How to Start a Microbrewery: 3 Dogs Brewing

This article is about steps for starting and opening a successful microbrewery taproom. In it, 3 Dogs Brewing Co describes how they went about opening their own microbrewery in a...

How to Start a Microbrewery: 3 Dogs Brewing

This article is about steps for starting and opening a successful microbrewery taproom. In it, 3 Dogs Brewing Co describes how they went about opening their own microbrewery in a...

World's Best Conical Fermentor: Introducing the...

I am very excited to be announcing today the launching of our fifth generation brewing system. Our goal at BREWHA is to bring you the world’s best small and medium...

World's Best Conical Fermentor: Introducing the...

I am very excited to be announcing today the launching of our fifth generation brewing system. Our goal at BREWHA is to bring you the world’s best small and medium...

Installation and Use of the Plate Chiller with ...

Installation and use of the plate chiller with the 5-in-1 fermenter BREWHA 5-in-1 product pageBREWHA Plate Chiller product pageBREWHA Cold Liquor Tank product page The last stage in...

Installation and Use of the Plate Chiller with ...

Installation and use of the plate chiller with the 5-in-1 fermenter BREWHA 5-in-1 product pageBREWHA Plate Chiller product pageBREWHA Cold Liquor Tank product page The last stage in...

Serving Direct from the BREWHA 5-in-1 Fermenter

Serving beer directly from the tank it was made in ensures you are serving the freshest beer possible...

Serving Direct from the BREWHA 5-in-1 Fermenter

Serving beer directly from the tank it was made in ensures you are serving the freshest beer possible...

How to Brew Kombucha

Brewing kombucha is similar in many ways to brewing beer (a sugar source is fermented) with the main difference being the microbes used to ferment. With beer, fermentation is completed...

How to Brew Kombucha

Brewing kombucha is similar in many ways to brewing beer (a sugar source is fermented) with the main difference being the microbes used to ferment. With beer, fermentation is completed...

Open a Dual-Permitted Brewery Distillery on Sam...

Sugar Hill Distillery (Apparition Brewing) has opened as the nation's first dual-permitted distillery and brewery, utilizing the same bonded space, as well as the same equipment to do both the...

Open a Dual-Permitted Brewery Distillery on Sam...

Sugar Hill Distillery (Apparition Brewing) has opened as the nation's first dual-permitted distillery and brewery, utilizing the same bonded space, as well as the same equipment to do both the...

Opening a Brewery in Atlanta, Georgia

Skint Chestnut Brewing Company in Powder Springs, Georgia is an amazing collaboration by brother-in-laws Doug and Mark. Their award-winning beer is incredibly delicious and they have created a fun and...

Opening a Brewery in Atlanta, Georgia

Skint Chestnut Brewing Company in Powder Springs, Georgia is an amazing collaboration by brother-in-laws Doug and Mark. Their award-winning beer is incredibly delicious and they have created a fun and...

Building a Dream Home Brewery in Retirement

My name is Steve Hollins I've been brewing for over 25 years. My wife and I live in Eldorado, Wisconsin, in the country and we decided to build the brew...

Building a Dream Home Brewery in Retirement

My name is Steve Hollins I've been brewing for over 25 years. My wife and I live in Eldorado, Wisconsin, in the country and we decided to build the brew...

Brewery Assembly and Install Instructions

In this video we will be setting up the BREWHA BIAC beer brewing system in 12 simple steps. The BIAC includes one fermenter so for customers with multiple BREWHA fermenters, the...

Brewery Assembly and Install Instructions

In this video we will be setting up the BREWHA BIAC beer brewing system in 12 simple steps. The BIAC includes one fermenter so for customers with multiple BREWHA fermenters, the...

How to Clean and Fill Beer Kegs

The BREWHA Keg Washer is an economical manual cleaner that is an effective way to clean kegs. While chemicals can be used to remove any long term build up, the...

How to Clean and Fill Beer Kegs

The BREWHA Keg Washer is an economical manual cleaner that is an effective way to clean kegs. While chemicals can be used to remove any long term build up, the...

Fulfilling a Lifelong Dream of Opening a Microb...

Kevin Greenaae of Oak Street Brewery in New Orleans, Louisiana discusses why he started his brewery in retirement, what...

Fulfilling a Lifelong Dream of Opening a Microb...

Kevin Greenaae of Oak Street Brewery in New Orleans, Louisiana discusses why he started his brewery in retirement, what...

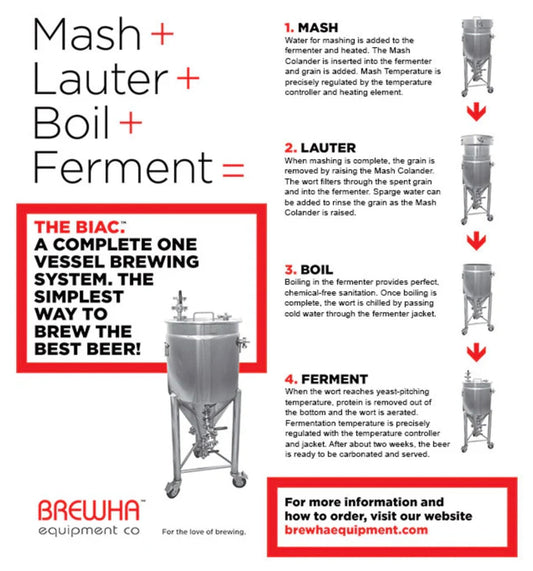

How to Make Beer with BREWHA

In this article we demonstrate why the BREWHA BIAC is the simplest way to make the best beer. We show in 12 steps how to make fantastic beer using the...

How to Make Beer with BREWHA

In this article we demonstrate why the BREWHA BIAC is the simplest way to make the best beer. We show in 12 steps how to make fantastic beer using the...

Simple and Concise Overview of the Beer Brewing...

This is a simple and concise overview of the beer brewing process. The BREWHA BIAC all in one complete beer brewing system is comprised of just two vessels (the jacketed...

Simple and Concise Overview of the Beer Brewing...

This is a simple and concise overview of the beer brewing process. The BREWHA BIAC all in one complete beer brewing system is comprised of just two vessels (the jacketed...

How to Build a Brewery Where Water is Scarce

How to start a brewery as shared by brewery owner Tim and head brewer Colin of the successful Barn Owl Brewing microbrewery taproom in Kelowna, BC. They talk about the...

How to Build a Brewery Where Water is Scarce

How to start a brewery as shared by brewery owner Tim and head brewer Colin of the successful Barn Owl Brewing microbrewery taproom in Kelowna, BC. They talk about the...

BREWHA BIAC Microbrewery Consultation and Beer ...

Learn how to install and operate your own successful BREWHA craft brewery by spending a fun and informative day brewing beer on the BREWHA BIAC. The price is US$150 for the workshop at...

BREWHA BIAC Microbrewery Consultation and Beer ...

Learn how to install and operate your own successful BREWHA craft brewery by spending a fun and informative day brewing beer on the BREWHA BIAC. The price is US$150 for the workshop at...

A New Model for Controlling Costs When Opening ...

Opening a new brewery can be a ginormous expense, but it doesn't have to be. In this video, Ed of Lake Martin Brewing in Alabama discusses how he controlled costs...

A New Model for Controlling Costs When Opening ...

Opening a new brewery can be a ginormous expense, but it doesn't have to be. In this video, Ed of Lake Martin Brewing in Alabama discusses how he controlled costs...

How BREWHA Fermenters Save You Money

When compared to the traditional four vessel brewing system, it is no surprise that the BREWHA system is cheaper to install (approximately 30% less) and that it takes up a smaller...

How BREWHA Fermenters Save You Money

When compared to the traditional four vessel brewing system, it is no surprise that the BREWHA system is cheaper to install (approximately 30% less) and that it takes up a smaller...

See next page for more articles on brewing equipment, how to brew beer and open a brewery