Articles on brewing and opening a brewery

How to Produce Liquor and Distill Delicious Spi...

This video provides a brief overview on how to produce delicious spirits / liquor (whiskey, brandy, vodka, rum etc.) using the BREWHA complete brewing and distilling system. The production of...

How to Produce Liquor and Distill Delicious Spi...

This video provides a brief overview on how to produce delicious spirits / liquor (whiskey, brandy, vodka, rum etc.) using the BREWHA complete brewing and distilling system. The production of...

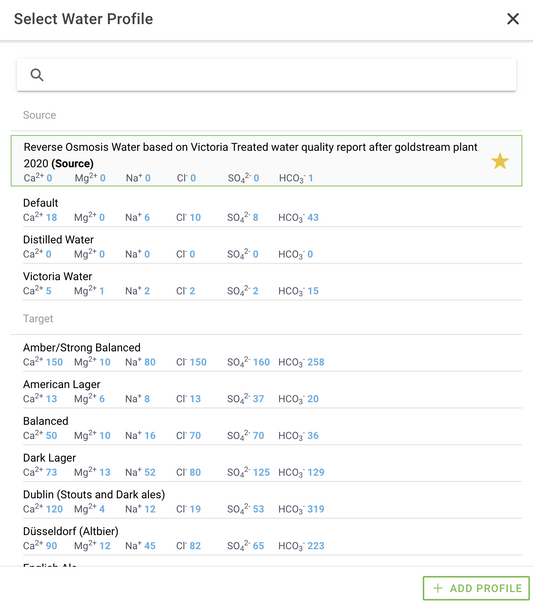

Brewing Water Chemistry

Water is probably the most important ingredient in beer, after all, it accounts for 90-95% of beer's volume. Water in not just a carrier or dilutant for flavor and alcohol,...

Brewing Water Chemistry

Water is probably the most important ingredient in beer, after all, it accounts for 90-95% of beer's volume. Water in not just a carrier or dilutant for flavor and alcohol,...

What Causes Fuses to Blow

Fuses blow when the draw (amps) is higher than the fuse is designed to permit. With the BREWHA brewing systems, this is typically caused by: 1. a short where the draw can...

What Causes Fuses to Blow

Fuses blow when the draw (amps) is higher than the fuse is designed to permit. With the BREWHA brewing systems, this is typically caused by: 1. a short where the draw can...

Countertop Beverage Chiller and Dispenser

This video describes the features and benefits of the Countertop Beverage Chiller and Dispenser, a fantastic countertop beverage chiller that can serve up to 25gal/hr (100L) of perfectly chilled beer, coffee, kombucha,...

Countertop Beverage Chiller and Dispenser

This video describes the features and benefits of the Countertop Beverage Chiller and Dispenser, a fantastic countertop beverage chiller that can serve up to 25gal/hr (100L) of perfectly chilled beer, coffee, kombucha,...

Eight Ways to Improve Mash Efficiency

Mash efficiency refers to the extent to which you are able to pull the sugars out of the malted grain and into the water. A high percentage of sugar recovery (75-90%) is called...

Eight Ways to Improve Mash Efficiency

Mash efficiency refers to the extent to which you are able to pull the sugars out of the malted grain and into the water. A high percentage of sugar recovery (75-90%) is called...

Brewing 5BBL of Craft Beer in the BREWHA BIAC

In this video you will see just how easy it is to use the BREWHA BIAC to brew 5BBL of craft beer. The BREWHA BIAC is an innovative brewing system...

Brewing 5BBL of Craft Beer in the BREWHA BIAC

In this video you will see just how easy it is to use the BREWHA BIAC to brew 5BBL of craft beer. The BREWHA BIAC is an innovative brewing system...

How to Install and Operate the BREWHA Keg Washer

This video demonstrates how to install and use the BREWHA Keg Cleaner. This manual keg cleaner is an economical way to manually clean kegs. The cleaner can stand alone or be...

How to Install and Operate the BREWHA Keg Washer

This video demonstrates how to install and use the BREWHA Keg Cleaner. This manual keg cleaner is an economical way to manually clean kegs. The cleaner can stand alone or be...

How to Import Brewing Equipment into Your Country

Importing BREWHA equipment into your country can seem intimidating when one approaches it for the first time. But while there are a few steps to take, and of course, a few...

How to Import Brewing Equipment into Your Country

Importing BREWHA equipment into your country can seem intimidating when one approaches it for the first time. But while there are a few steps to take, and of course, a few...

Best Way to Clean and Sanitize Brewing Equipment

One of the useful features of the BREWHA BIAC is that boiling can occur inside the fermenter which makes sanitation a snap—the heat of the boil will sanitize the fermenter so...

Best Way to Clean and Sanitize Brewing Equipment

One of the useful features of the BREWHA BIAC is that boiling can occur inside the fermenter which makes sanitation a snap—the heat of the boil will sanitize the fermenter so...

The Freshest Beer Possible

The freshest beer possible... is beer right out of the fermentor. No transfer hoses, kegs or brite tanks to contaminate, the BREWHA MB BIAC all in one brew system lets...

The Freshest Beer Possible

The freshest beer possible... is beer right out of the fermentor. No transfer hoses, kegs or brite tanks to contaminate, the BREWHA MB BIAC all in one brew system lets...

A Dream Come True — 3 Dogs Community Brewpub

When the owners of 3 Dogs Brewing wanted to start a community microbrewery in a strip mall, they had to choose brewing equipment that met their budget and fit in...

A Dream Come True — 3 Dogs Community Brewpub

When the owners of 3 Dogs Brewing wanted to start a community microbrewery in a strip mall, they had to choose brewing equipment that met their budget and fit in...

How to Assemble a Grain Roller Mill for a Micro...

This video describes how to assemble a grist/malt roller mill for a microbrewery or brewpub. Starting with a Crankandstein 328G eight inch, three roller, fully geared mill, instructions are then given on...

How to Assemble a Grain Roller Mill for a Micro...

This video describes how to assemble a grist/malt roller mill for a microbrewery or brewpub. Starting with a Crankandstein 328G eight inch, three roller, fully geared mill, instructions are then given on...

Starting a Veteran-Owned Brewery in Texas

In this video, Veteran JD McBride discusses how and why he opened his brewery taproom, Fire Base Brewing in Temple, Texas. He talks about his time...

Starting a Veteran-Owned Brewery in Texas

In this video, Veteran JD McBride discusses how and why he opened his brewery taproom, Fire Base Brewing in Temple, Texas. He talks about his time...

Overview on How to Make All-Grain Beer at Home

The purpose of the BREWHA BIAC system is to provide brewers with a more enjoyable brewing experience by giving maximum control and superior results while simplifying the brewing process and...

Overview on How to Make All-Grain Beer at Home

The purpose of the BREWHA BIAC system is to provide brewers with a more enjoyable brewing experience by giving maximum control and superior results while simplifying the brewing process and...

A New Model for Controlling Costs When Opening ...

Opening a new brewery can be a ginormous expense, but it doesn't have to be. In this video, Ed of Lake Martin Brewing in Alabama discusses how he controlled costs...

A New Model for Controlling Costs When Opening ...

Opening a new brewery can be a ginormous expense, but it doesn't have to be. In this video, Ed of Lake Martin Brewing in Alabama discusses how he controlled costs...

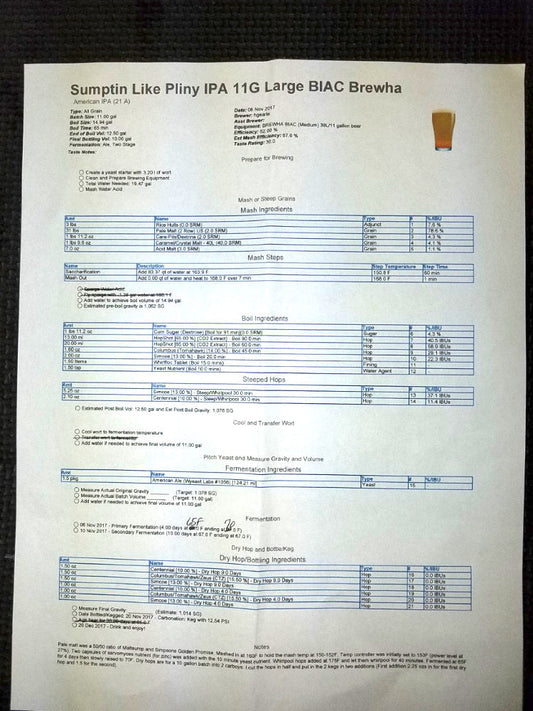

Sumptin Like Pliny IPA 11G Large BIAC recipe

These four recipes were submitted by BREWHA customer Harold for Chicago, IL. The first recipe was originally based on Pliny the Elder, but has evolved. It is a great beer!...

Sumptin Like Pliny IPA 11G Large BIAC recipe

These four recipes were submitted by BREWHA customer Harold for Chicago, IL. The first recipe was originally based on Pliny the Elder, but has evolved. It is a great beer!...

How to Effectively Clean Electric Heating Elements

Cleaning beer brewing elements is not difficult, especially with the BREWHA system where an element can be easily removed from the vessel simply be removing the clamp that holds it in place. Once...

How to Effectively Clean Electric Heating Elements

Cleaning beer brewing elements is not difficult, especially with the BREWHA system where an element can be easily removed from the vessel simply be removing the clamp that holds it in place. Once...

Introduction to Producing Liquor

BREWHA fermenters (3-in-1 and 4-in-1) can be used for distillation and producing spirits such as whiskey— scotch (from barley), bourbon (barley and corn) and rye (from rye)—rum (cane sugar), brandy (fruit) and vodka...

Introduction to Producing Liquor

BREWHA fermenters (3-in-1 and 4-in-1) can be used for distillation and producing spirits such as whiskey— scotch (from barley), bourbon (barley and corn) and rye (from rye)—rum (cane sugar), brandy (fruit) and vodka...

Installing a Portable Fermentation Temperature ...

For most styles of beer, a chilling system is important for producing a great tasting beverage. In fact, aside from proper sanitation, temperature control is arguably the single most important criteria for...

Installing a Portable Fermentation Temperature ...

For most styles of beer, a chilling system is important for producing a great tasting beverage. In fact, aside from proper sanitation, temperature control is arguably the single most important criteria for...

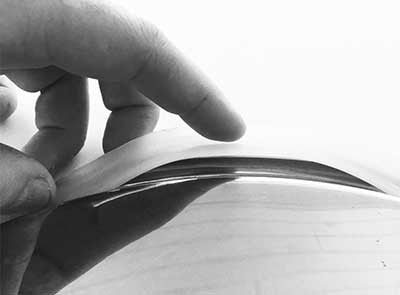

Good Crush Size for High Efficiency and Bed Flu...

The below image is a high definition picture of the image shown on this page of the BREWHA website. It shows a good crush size that removes the grain husk...

Good Crush Size for High Efficiency and Bed Flu...

The below image is a high definition picture of the image shown on this page of the BREWHA website. It shows a good crush size that removes the grain husk...

Troubleshooting the March 815

March builds high quality pumps that will provide years of dependable service. Unlike cheaper pumps that can be frustrating to operate (due to such reasons as poor motor and body alignment...

Troubleshooting the March 815

March builds high quality pumps that will provide years of dependable service. Unlike cheaper pumps that can be frustrating to operate (due to such reasons as poor motor and body alignment...

How to Add Priming Sugar to Bottled Beer for Ca...

Customers who are bottling their beer sometimes ask how they should add priming sugar in order to carbonate the beer. There are a few ways to accomplish this. A first method is...

How to Add Priming Sugar to Bottled Beer for Ca...

Customers who are bottling their beer sometimes ask how they should add priming sugar in order to carbonate the beer. There are a few ways to accomplish this. A first method is...

Securing Sanitary Clamps Against Accidental Loo...

A customer recently informed us that some friends (who were new to brewing) had loosened one of the sanitary clamps on the 'wrong' (that is, nearest to the fermenter) side of the valve....

Securing Sanitary Clamps Against Accidental Loo...

A customer recently informed us that some friends (who were new to brewing) had loosened one of the sanitary clamps on the 'wrong' (that is, nearest to the fermenter) side of the valve....

Colander Water Level Controller Manual

The BREWHA Colander Water Level Sensor provides automatic control of the pump when recirculating wort during mash. If the wort level drops below the end of the probes, the pump will...

Colander Water Level Controller Manual

The BREWHA Colander Water Level Sensor provides automatic control of the pump when recirculating wort during mash. If the wort level drops below the end of the probes, the pump will...

Brewing an American Amber—Evaluation Part 5

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode the completed beer is sampled and reviewed with comments on what...

Brewing an American Amber—Evaluation Part 5

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode the completed beer is sampled and reviewed with comments on what...

Brewing an American Amber—Chill & Pitch Part 4

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode the boiled wort is cooled down to yeast pitching temperature, yeast...

Brewing an American Amber—Chill & Pitch Part 4

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode the boiled wort is cooled down to yeast pitching temperature, yeast...

Brewing an American Amber—Boiling Part 3

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode the mash is lautered (separate grain from water), the grain is...

Brewing an American Amber—Boiling Part 3

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode the mash is lautered (separate grain from water), the grain is...

Brewing an American Amber Ale—Mashing Part 2

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode Doug helps us mash in and Matt stops by to give...

Brewing an American Amber Ale—Mashing Part 2

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series. In this episode Doug helps us mash in and Matt stops by to give...

Unboxing of the BREWHA BIAC brewing system Part 1

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series and "will see us leap right into the deep end of homebrew technology with...

Unboxing of the BREWHA BIAC brewing system Part 1

This video was filmed by heavyGFILMS as part of its Le Gourmet TV channel 'Brewhouse' series and "will see us leap right into the deep end of homebrew technology with...

How to Clean and Sanitize a Beer Transfer Hose

When racking beer, one primary source of infection can be the transfer hose that is used. Hoses can easily develop knicks and cracks internally that are hard to spot, harbor...

How to Clean and Sanitize a Beer Transfer Hose

When racking beer, one primary source of infection can be the transfer hose that is used. Hoses can easily develop knicks and cracks internally that are hard to spot, harbor...

Water Flow Meter Specification Sheet

This accurate and reliable Flow Meter is useful for metering the amount of water going into your brew system. It can be particularly useful when adding sparge water to add the...

Water Flow Meter Specification Sheet

This accurate and reliable Flow Meter is useful for metering the amount of water going into your brew system. It can be particularly useful when adding sparge water to add the...

Sparging with the BIAC

While not absolutely necessary, some brewers prefer to rinse or 'sparge' their grain at the end of the mash period to recover as much sugar as possible. While cold water can...

Sparging with the BIAC

While not absolutely necessary, some brewers prefer to rinse or 'sparge' their grain at the end of the mash period to recover as much sugar as possible. While cold water can...

Installing the Fermenter Lid Gasket

All models of the BREWHA 3-in-1 fermenter have a silicone lid gasket for sealing the lid and providing up to 3psi of pressure for racking beer into kegs. If the lid...

Installing the Fermenter Lid Gasket

All models of the BREWHA 3-in-1 fermenter have a silicone lid gasket for sealing the lid and providing up to 3psi of pressure for racking beer into kegs. If the lid...

Preventing Scorched Wort and Burnt Flavor in Yo...

After four weeks of eager anticipation, there are few things more devastating to a brewer than discovering an unwanted microbial infection or tasting burnt/smokey notes in your latest brew. The BIAC...

Preventing Scorched Wort and Burnt Flavor in Yo...

After four weeks of eager anticipation, there are few things more devastating to a brewer than discovering an unwanted microbial infection or tasting burnt/smokey notes in your latest brew. The BIAC...

Heating and Chilling Methods for the 5BBL BIAC

There has been some discussion online about the benefit of circulating wort inside the BIAC fermenter during chilling to reduce the chill time so we put it to the test in...

Heating and Chilling Methods for the 5BBL BIAC

There has been some discussion online about the benefit of circulating wort inside the BIAC fermenter during chilling to reduce the chill time so we put it to the test in...

Controlling Vorlauf and Lauter Rates to Prevent...

Not long ago Dave Miller sent me a link to an article he wrote on vorlauf and lautering that has really helped with questions around increasing lauter rates and preventing stuck mashes. In...

Controlling Vorlauf and Lauter Rates to Prevent...

Not long ago Dave Miller sent me a link to an article he wrote on vorlauf and lautering that has really helped with questions around increasing lauter rates and preventing stuck mashes. In...

Assembling the Water Pressure Reducing Valve

Every hose and tank is designed with a maximum allowable working pressure (MAWP), which if exceeded, will cause damage and could even pose a safety hazard. The BREWHA tank jackets...

Assembling the Water Pressure Reducing Valve

Every hose and tank is designed with a maximum allowable working pressure (MAWP), which if exceeded, will cause damage and could even pose a safety hazard. The BREWHA tank jackets...

Installing Your BIAC Complete All-in-One Brewery

In this video we will be looking at how to setup the BREWHA BIAC. While today we are setting up a 5 barrel BIAC, most of the features and fittings...

Installing Your BIAC Complete All-in-One Brewery

In this video we will be looking at how to setup the BREWHA BIAC. While today we are setting up a 5 barrel BIAC, most of the features and fittings...

How to Resurrect Yeast and Keep Fermentation Alive

Most brewers have had the unhappy experience where fermentation is proceeding along nicely, then quite suddenly and unexpectedly stops shy of the target gravity. In a panic, the fermenter lid is...

How to Resurrect Yeast and Keep Fermentation Alive

Most brewers have had the unhappy experience where fermentation is proceeding along nicely, then quite suddenly and unexpectedly stops shy of the target gravity. In a panic, the fermenter lid is...

Benefits of the BREWHA BIAC Brewing System

The BIAC (Brew In A Conical) complete brewing system makes brewing simpler, easier and more enjoyable. Some of the many benefits of this system include:

Benefits of the BREWHA BIAC Brewing System

The BIAC (Brew In A Conical) complete brewing system makes brewing simpler, easier and more enjoyable. Some of the many benefits of this system include: