How to Carbonate Beer in the BREWHA Fermenter

The BREWHA fermenters are designed to withstand up to 14.9psi of pressure. This is enough pressure to fully carbonate beer, and once carbonated, it is ready to serve.

Introduction on how to carbonate beer directly in the fermenter

Carbonating beer directly in the fermenter is an efficient method that saves time and reduces the risk of contamination. This technique, often called 'spunding' or 'natural carbonation,' allows you to achieve perfect carbonation levels while maintaining the beer's quality and flavor profile.

What you'll need to carbonate in the fermenter

- Fermenter with pressure capability (conical or unitank)

- Spunding valve or pressure relief valve

- Pressure gauge

- CO2 tank and regulator (optional for topping off)

- Sanitized sampling valve

- Hydrometer or refractometer

The carbonation process

The beer can be carbonated in the fermenter through force carbonation with a CO2 tank once fermentation is complete, or, with care, the beer can be naturally or self carbonated by capturing the gas released during fermentation.

Whether you are naturally or force self carbonating, it is VERY IMPORTANT to always have the Pressure and Vacuum Safety Valve attached directly to one of the lid ports and to test the valve regularly to ensure it is relieving pressure at or before the maximum pressure (Note: the adjustable pressure regulator can be adjusted to crack at various pressures from 3-15psi).

Step 1: Set up your pressure relief valve and pressure guage

On the second 1.5" lid port, a valve is attached, then a Fermenter Gas in Post. Or if you want to be able to read the pressure in the tank first a 1.5" sanitary tee with a pressure gauge (or spunding valve apparatus) attached to the vertical side of the tee (1/4" thread stainless steel pressure gauges can be purchased here and can be connected to a 1.5"TCx0.25" coupling), and then a Fermenter Gas in Post attached to the horizontal port on the tee.

Even if naturally carbonating, the Gas in Post will be used to add CO2 volumes if fermentation does not deliver quite enough and/or to maintain gas pressure when racking to kegs lowers the beer level in the tank; removed from the tank, this tee setup can also be used to test a Pressure and Vacuum Safety Valve to ensure it is functioning properly.

Step 2: Monitor fermentation progress

If capturing the gas during fermentation (this is faster than force carbonating after fermentation is complete), it is recommended to use a blow off hose until late in fermentation (e.g. when the gravity is around 1.020-1.025—a lower starting gravity with a small head space, and a higher starting gravity with a large head space) to reduce the risk of over pressurizing and damaging the tanks.

While the pressure relief should let any excess gas off, waiting until your gravity is lower, will help minimize risk in the unlikely event of a relief valve failure (it is advised to regularly inspect the proper functioning of your safety valve).

Step 3: Pressurize (if not completed by fermentation gas capture)

If force carbonating, carbonating stones can be used (customers have reported that attaching the BREWHA Aeration Stone to the racking port works well and the tank is fully carbonated in 48-72 hours when held at 5C/41F), however, adding CO2 from above is not much slower, will eliminate the risk of gas stirring up any sediment/yeast that has settled out, and reduces the amount of flavor and aroma compounds that might be scrubbed out of the beer by gas bubbles.

For adding CO2, either a commercial gas regulator and tank can be used (about $300-400 for both of them and $30 per 20lb of gas fill; local fire extinguisher companies will often fill these) which is cheapest in the long run if using larger amounts of gas, or a mini regulator like one made by Kegland (Mini 360, about $80 for regulator and $15 per ~lb of gas) can connect to either small cartriges or the larger 'blue' ones used by Soda Stream and their competitors.

Step 4: Temperature control

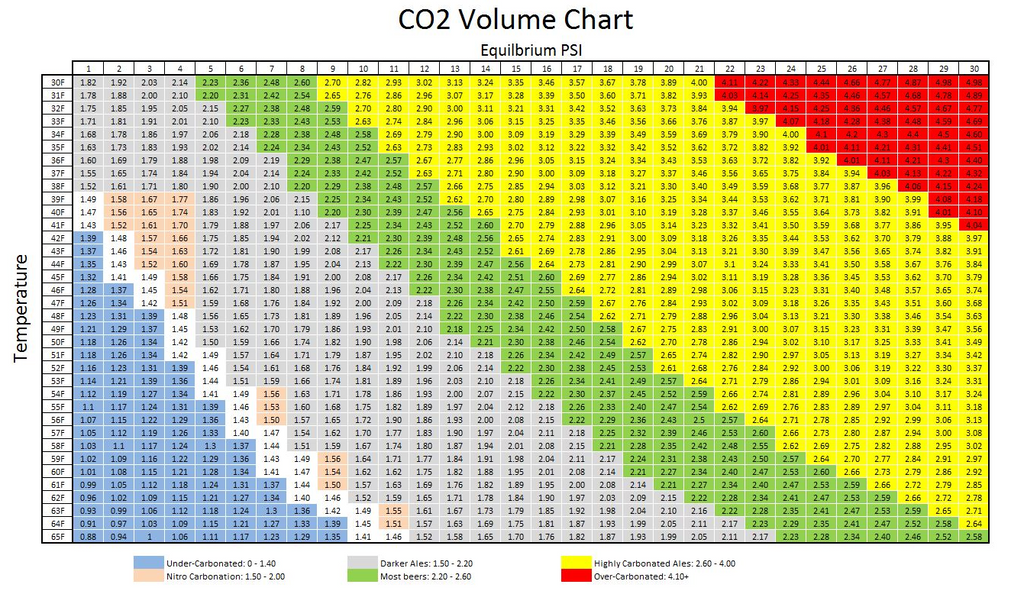

Gas pressure charts (see example at bottom of the page from Brewer's Friend) inform the brewer what pressure to set the regulator at, relative to the temperature of the beer and the desired final volume. For most ales when crashing to 4C/40F this will mean the regulator should be set to 12psi although styles like stouts will be lower and a few styles that require higher pressure will need to have some gas added in the keg as the fermenter pressure limit is 14.9psi and the non-adjustable regulators will often crack at lower than the maximum set pressure.

The relief valve should be tested regularly to determine its cracking/opening pressure and the regulator should be set below this value to ensure gas is not wasted; regulators and pressure gauges should also be tested regularly and higher quality regulators will allow more accurate control. (Note: regulators with adjustable pressure settings can be purchased here.)

Once CO2 is added (either naturally or forced in), the Brewery Water Chiller can circulate cold water through the jacket to reduce the temperature of the beer (a removable neoprene insulating jacket can be installed at this point to help the beer get within a few degrees of freezing under standard room conditions)—this will reduce carbonation time and allow more volumes of CO2 (CO2 dissolves more readily at lower temperature) and help remaining yeast to drop out of suspension (crash cooling).

Even if not wanting to carbonate in the fermenter, maintaining a few psi of pressure in the fermenter when cooling will eliminate the risk of a vacuum forming as the pressure offsets the vacuum created by water/beer shrinking as it cools.

Once cooled, yeast can be removed through the bottom/dump valve and the racking arm flushed out to remove any yeast settled in there and the beer can be transferred to kegs for serving (keep the CO2 connected to the fermenter while kegging to maintain pressure in the tank as the beer level drops — this will help maintain carbonation levels and reduce foaming in the fermenter which can stir up residual yeast).

Pressure settings guide

Here are typical pressure settings for different beer styles at 40°F (4°C):

- British Ales: 7-9 PSI (1.8-2.2 volumes CO2)

- American Ales: 10-12 PSI (2.2-2.6 volumes CO2)

- Lagers: 13-15 PSI (2.6-2.8 volumes CO2)

Troubleshooting common issues

Under-carbonation

If your beer isn't reaching target carbonation levels:

- Check if fermentation is still active

- Verify pressure relief valve (PRV) settings

- Ensure no leaks on the fermenter (loose clamps; using foaming spray solution like Star San on connections can help spot leaks by the bubbling)

- Consider adding priming sugar or force carbonating

Over-carbonation

If pressure builds too quickly:

- Lower the PRV setting

- Vent excess pressure carefully

- Check for temperature fluctuations

Benefits of fermenter carbonation

- Reduces oxidation risk

- Saves time compared to bottle conditioning

- Provides consistent carbonation levels

- Eliminates need for priming sugar calculations

- Allows for easy pressure transfers

Safety considerations

Important: Always ensure your fermenter is rated for pressure and your PRV is functioning as designed. Never exceed the manufacturer's recommended pressure limits. Always wear safety glasses when working with pressurized vessels, and have a pressure relief valve as a backup safety measure.

Conclusion for carbonating in the fermenter

Carbonating beer in the fermenter is an excellent technique for homebrewers and commercial brewers alike. With proper equipment and careful monitoring, you can achieve professional-quality carbonation while streamlining your brewing process. Remember to always prioritize safety and follow your equipment manufacturer's guidelines.

For more brewing tips and equipment recommendations, explore our full range of fermentation vessels and carbonation equipment designed to help you brew better beer.

Video: Cleaning and filling Sanke kegs

How to fill Sanke kegs directly from the 4-in-1 conical fermentor

The freshest beer possible