Plate Heat Exchanger Wort Chiller

Plate Heat Exchanger Wort Chiller

Couldn't load pickup availability

Overview of the plate heat exchanger wort chiller

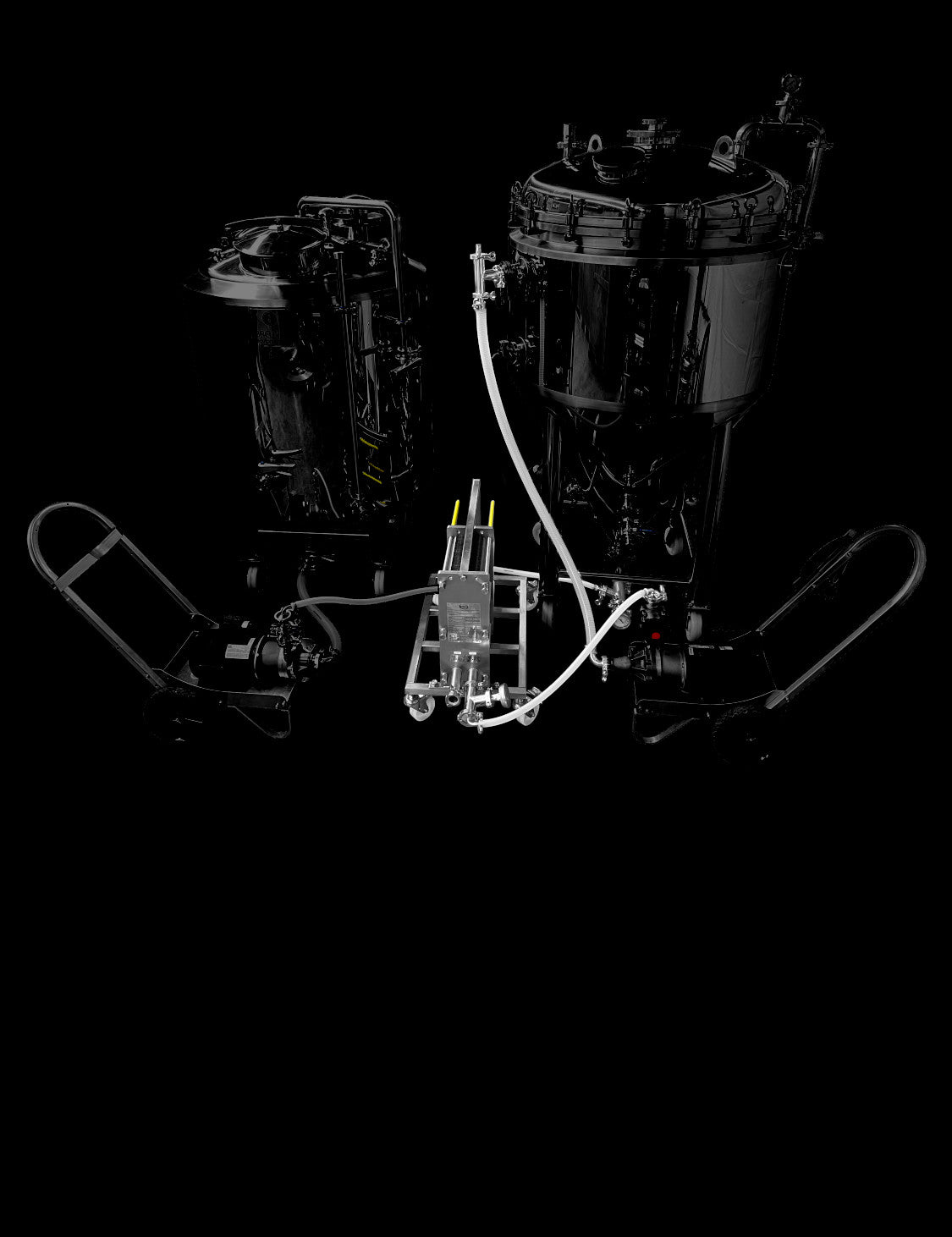

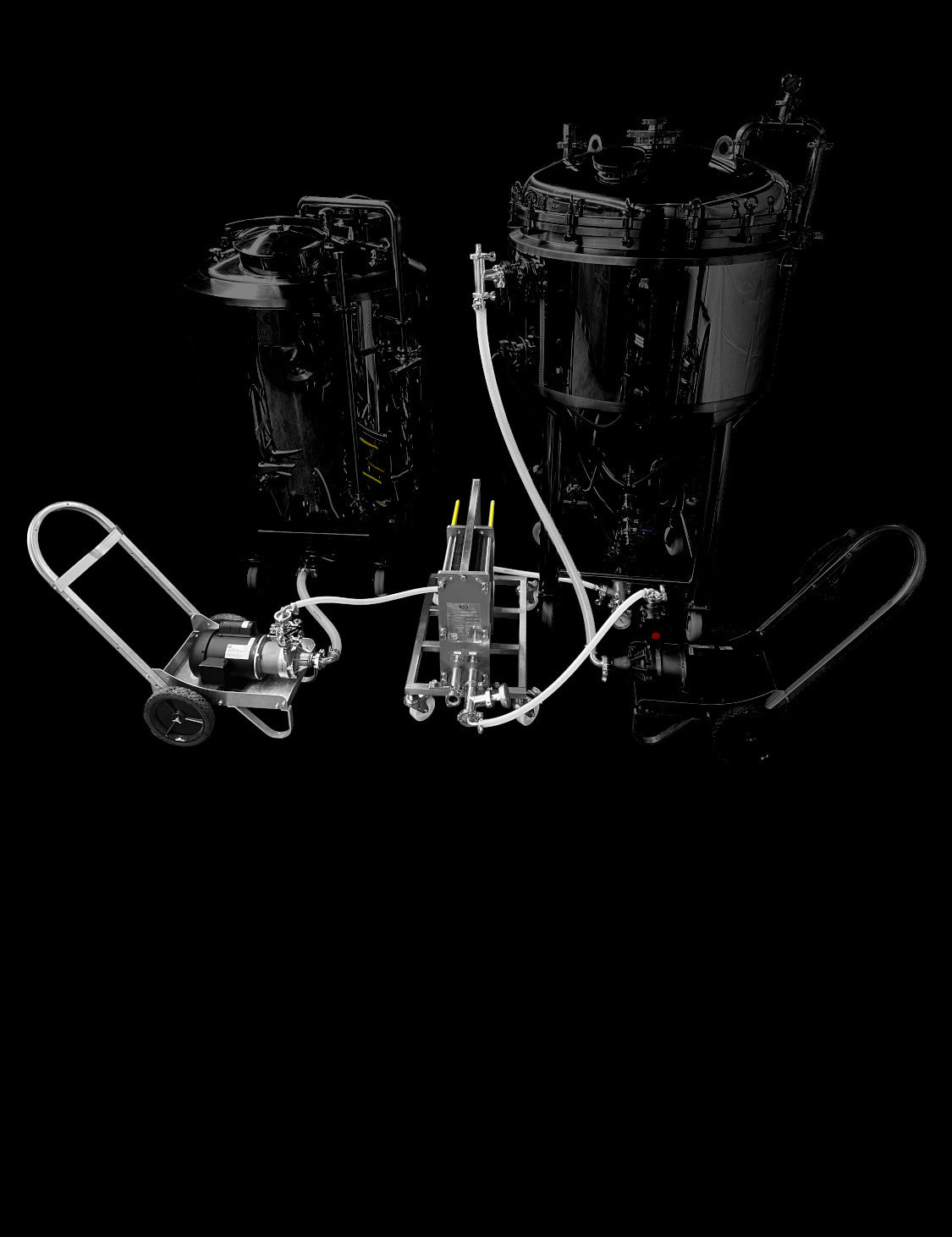

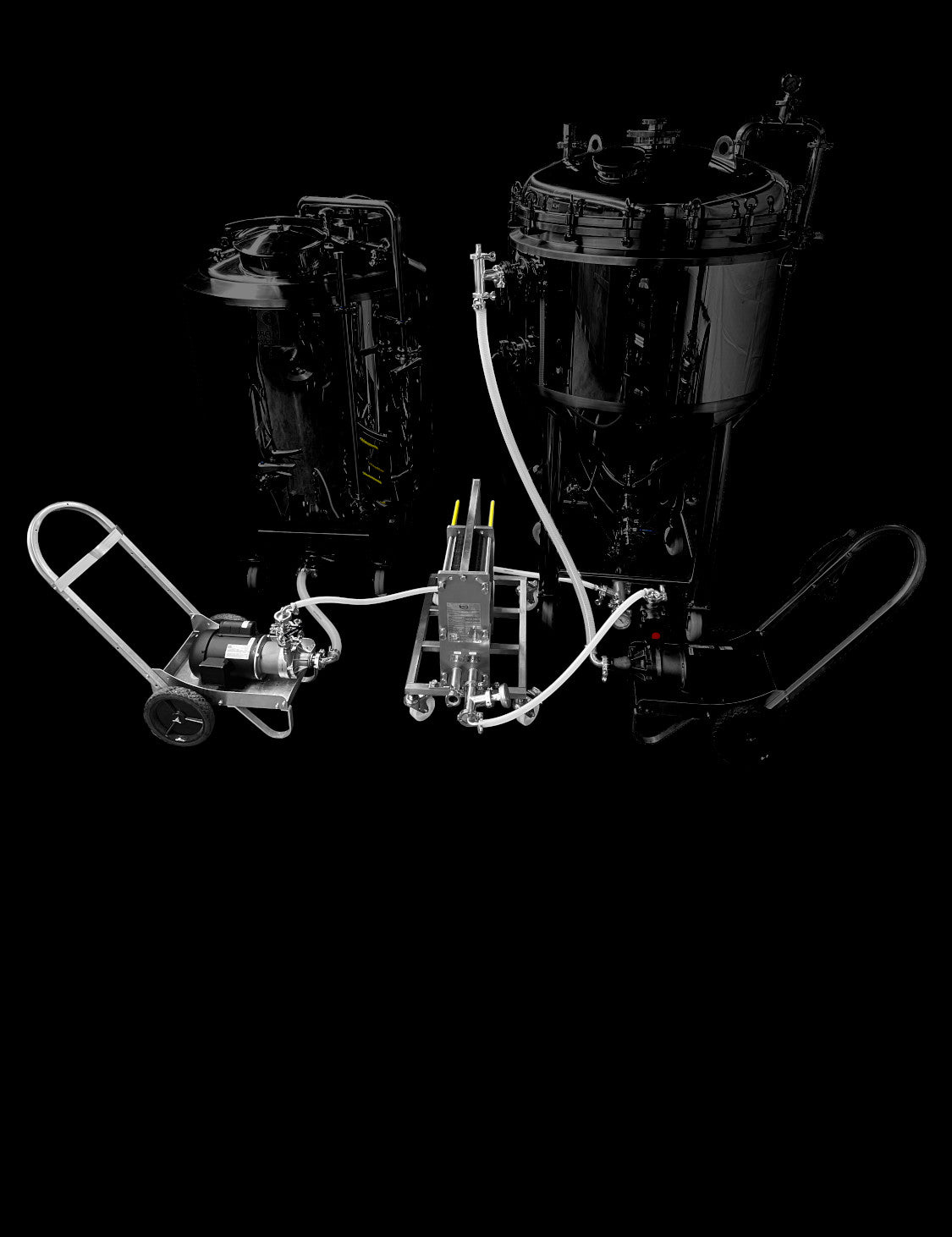

These 100% stainless steel, gasketed, portable, counter-current heater exchangers / wort chillers use cold water either from one of our cold liquor storage tanks, or tap water if cold enough, to knock down the temperature of wort, or other media post-boil. This high efficiency plate chiller design with solid stainless steel frame (not just cladded steel) is capable of knocking down up to 15BBL (18HL) of water or wort in under an hour.

The single 1-stage high efficiency chiller design is suitable for one cooling media (for example tap cold water) and the dual 2-stage heat exchanger design is useful where two sources of chilled water are necessary to complete wort knock down, for example a mix of tap and pre-chilled ice water. The dual stage plate exchanger is used where tap water is not cold enough and/or one's pre-chilled cold water source is not large enough.

As an added benefit in certain applications such as a brewery, if one uses the next batch's brew water on the cold side to cool the wort, and transfers it from the hot side exit into a waiting brew tank and hot liquor tank, less energy will be required when heating on next brew day, saving electricity.

These exchangers are in a solid frame and come with removable stainless steel casters for high mobility and portability in your brewery.

The Tap Water to Chiller Hose Assembly includes hose and fittings to connect the fermenter to a pump (brewery pump not included), pump to plate chiller, and plate chiller back to the fermenter. On the chillant/cold water side it includes a short section of hose with a garden hose connector.

The Pump and Chiller Water Hose Assembly includes the hoses and fittings to connect the fermenter to the plate chiller, plus a 1hp March 7S pump and pump cart, and hoses to bring pre-chilled water from our cold liquor tank to the pump and from the pump to the cooling side of the plate chiller.

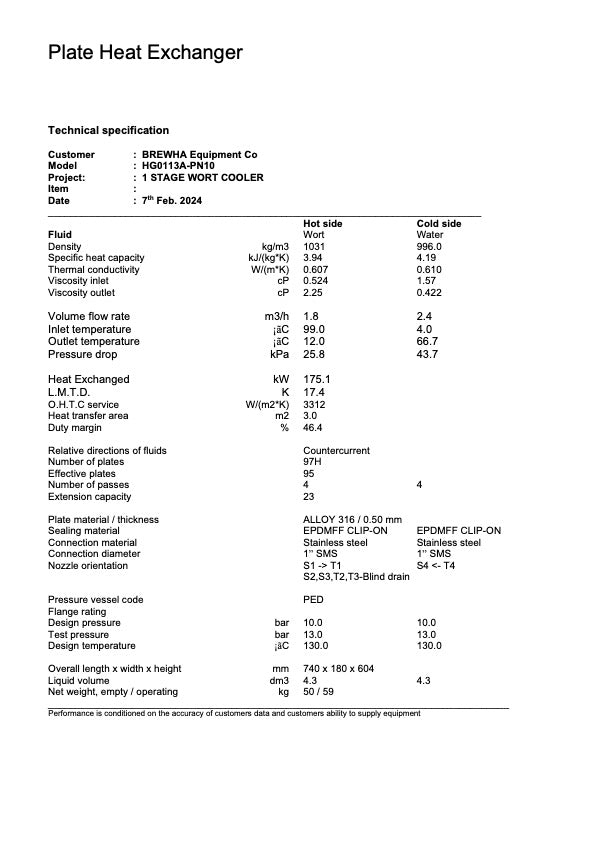

Plate Heat Exchanger Wort Chiller Design Specifications

Direction of fluids: Countercurrent

Plate material / thickness: Alloy 316 / 0.50mm

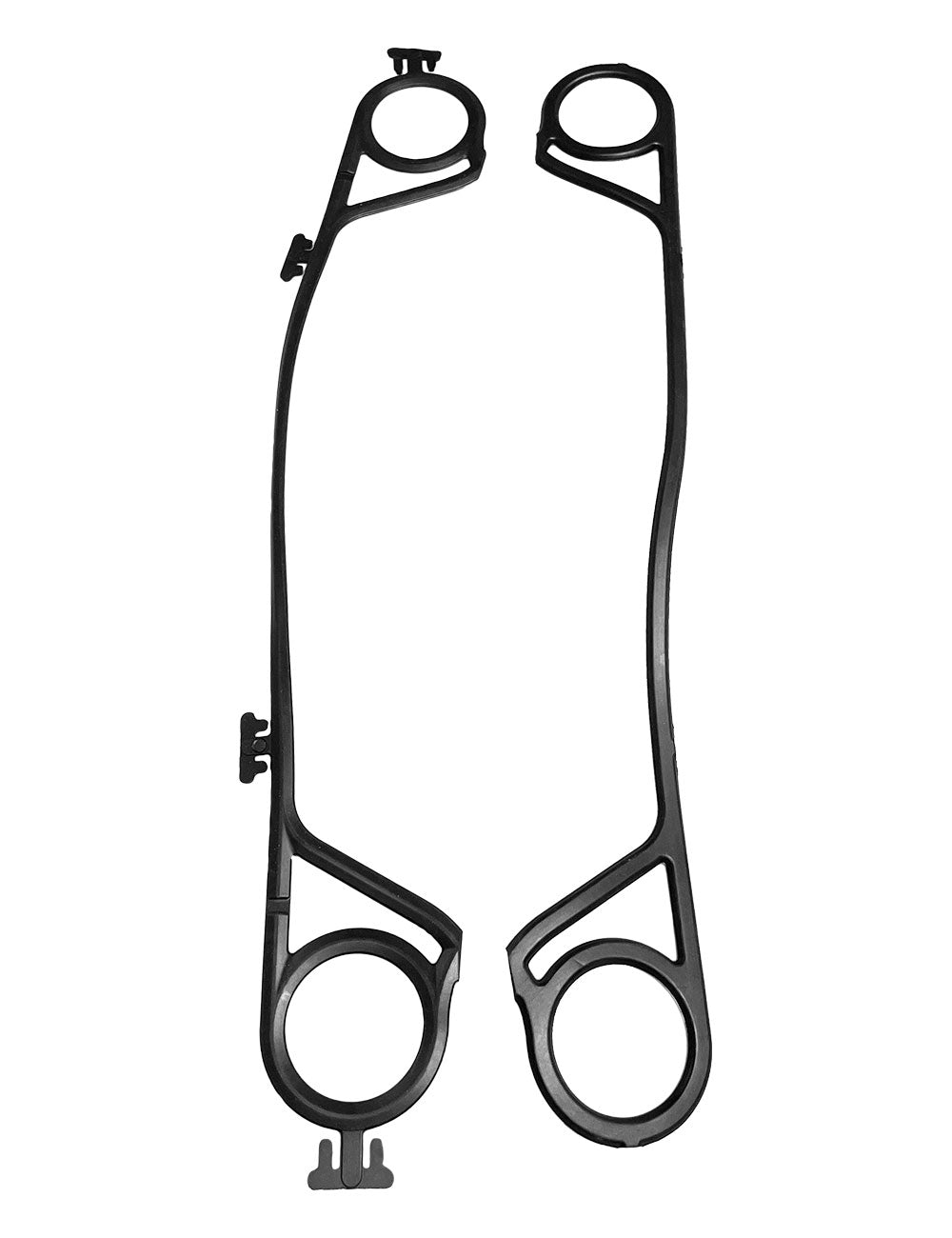

Sealing material: EPDMFF Clip-on

Connection material: 304

Connection diameter: 1" SMS Sanitary Tri-clamp

Design pressure: 10 bar

Test pressure: 13 bar

Design maximum temperature: 130°C / 266°F

Single 1-Stage Plate Heat Exchanger Chiller

Volume flow rate hot side / cold side: 1.8m3 flow per hour / 2.4m3 flow per hour

Hot side inlet / outlet temperature / pressure drop: 99°C/12°C/25.8kPa

Cold side inlet / outlet temperature / pressure drop: 4°C/67°C/43.7kPa

Heat Exchanged: 175.1 kW

Heat transfer area: 3.0m2 / 32.0ft2

Number of effective high efficiency thermal heat transfer plates: 95

Number of passes: 4

Dimensions (lxwxh in mm): 740x180x704

Liquid volume per side: 4.3L

Gross weight: 59kg

Double 2-Stage Plate Heat Exchanger Chiller

Section 1 (tap)

Volume flow rate hot side / cold side: 1.8m3 flow per hour / 1.5m3 flow per hour

Hot side inlet / outlet temperature / pressure drop: 99°C/30°C/37.3kPa

Cold side inlet / outlet temperature / pressure drop: 15°C/95°C/25.6kPa

Heat Exchanged: 175.1 kW

Heat transfer area: 4.6m2 / 49.0ft2

Number of effective high efficiency thermal heat transfer plates: 143

Section 2 (ice water)

Volume flow rate hot side / cold side: 1.8m3 per hour / 1.3m3 per hour

Hot side inlet / outlet temperature / pressure drop: 30°C/12°C/37.5kPa

Cold side inlet / outlet temperature / pressure drop: 4°C/27.9°C/18.9kPa

Heat Exchanged: 36.29 kW

Heat transfer area: 2.5m2 / 27.0ft2

Number of effective high efficiency thermal heat transfer plates: 79

Number of plate passes: 6*12H/4

Dimensions (l by w by h in mm): 1140x180x704

Liquid volume per side: 9L

Gross weight: 100kg

Replacement plates and gaskets are for the BREWHA Single Stage (BHSSSSHE) and Double Stage (BHSSDSHE) Heat Exchangers only.

Share