Sparging with the BIAC

While not absolutely necessary, some brewers prefer to rinse or 'sparge' their grain at the end of the mash period to recover as much sugar as possible. While cold water can be used, it is generally recommended to use hot water near 75°C/167°F as sugars will be recovered more readily and the grain bed kept more fluid, allowing easier passage of water.  Sparge water can be added directly to the Mash Colander with a hose or pitcher, however, this can be cumbersome and require an extra pre-heating step. Some customers use a separate HERMS hot liquor tank kettle (hot water) to preheat and measure their sparge water.

Sparge water can be added directly to the Mash Colander with a hose or pitcher, however, this can be cumbersome and require an extra pre-heating step. Some customers use a separate HERMS hot liquor tank kettle (hot water) to preheat and measure their sparge water.

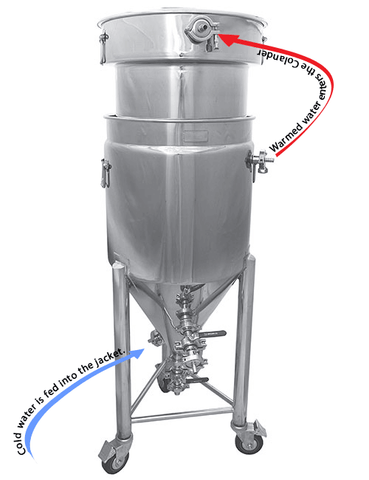

An easy and efficient means of adding hot sparge water in the BREWHA complete brewing system, however, is achieved by just using the BREWHA conical fermentor jacket. By connecting a fresh water source (e.g. municipal or treated water) to the lower, inlet port of the jacket, and then connecting the jacket exit port to the Mash Colander inlet, water can be fed into the jacket and is pre-heated as it rises up through the jacket. The temperature sensor and heating element on the inside of the conical fermentor (it is mostly likely set to 75°C/167°F for 'mashing out' in preparation for boil) will keep the temperature of the wort inside the fermentor at the set temp, and the wort will heat the sparge water through the wall of the vessel. Sparge water should be fed slowly as the sparge and lauter should not be rushed, and the Mash Colander can be slowly raised as water is added, creating more room in the conical fermentor for water and preventing spill over.

Sparge water can be added continually as the Colander is raised, and the Colander removed once the pre-boil volume is met, however, this can result in a mess as the Colander will still be draining as it is removed. A more precise method is to use a program like Beersmith to calculate your exact sparge volume to be added, and then use a water flow meter to monitor the exact amount of water being added. This way the entire amount in the Colander can be drained into the fermenter, and the Colander removed when empty of water. (Flow calculation should be started once the water begins to enter the Colander since the jacket needs to be filled first. Also remember to always use a Water Pressure Regulator to prevent overpressurizing/damaging the jacket, and control sparge water flow with a valve before the jacket, not after — don't close the valve on the Colander as this could cause back pressure inside the jacket. And remember to thoroughly clean and rinse the jacket before first use using hot water and chemical—alkaline and acid—cleaners. If using glycol or other non-water chillants in the jacket, this method is not recommended as sparge water could be contaminated.)

This way the entire amount in the Colander can be drained into the fermenter, and the Colander removed when empty of water. (Flow calculation should be started once the water begins to enter the Colander since the jacket needs to be filled first. Also remember to always use a Water Pressure Regulator to prevent overpressurizing/damaging the jacket, and control sparge water flow with a valve before the jacket, not after — don't close the valve on the Colander as this could cause back pressure inside the jacket. And remember to thoroughly clean and rinse the jacket before first use using hot water and chemical—alkaline and acid—cleaners. If using glycol or other non-water chillants in the jacket, this method is not recommended as sparge water could be contaminated.)

5 comments

Thank you very much for the invitation :). Best wishes.

PS: How are you? I am from France :)

Hi Colin, yes, it can be mixed in a separate tank and then added if you need a lot of adjustment.

Is there any way to acidify the sparge water? I’m assuming not if it’s direct from municipal water supply, but it could be pumped over from a separate vessel (where it has been acidified)?

Hi Paul — when raising the Colander during sparge, keeping approx 1" of sparge water on top of the grain bed (topping it up as it drains down) as long as possible ensures even distribution of the water down through the grain bed.

When sparging, is it best to have a device to sprinkle water over grain or just trickle by pinching the valve back from the pump pulling from the jacket?