March 815 1/25hp Water and Beer Pump

March 815 1/25hp Water and Beer Pump

Couldn't load pickup availability

March builds high quality pumps that will provide years of dependable service. Unlike cheaper pumps that can be frustrating to operate (due to such reasons as poor motor and body alignment leading to binding, poorly cast and low quality parts being easily broken, under powered motors leading to stoppage when grain enters the pump head and motors that readily burn out) these pumps are brewery workhorses that will provide years of dependable service.

The 815-SS-C homebrewery pump has a maximum flow rate of 8gpm/30lpm or head of 13.5ft/4.1m (approx 4gal/min at 5psi) and is a great size for Small, Medium and Large (20-60L/5-15 gallon) brewing systems. Pump comes with one 1/2" MPT outlet and one 3/4" MPT inlet post, stainless steel impeller enclosure and 5-15 plug (North America). Click here to see a larger, more powerful brewery pump.

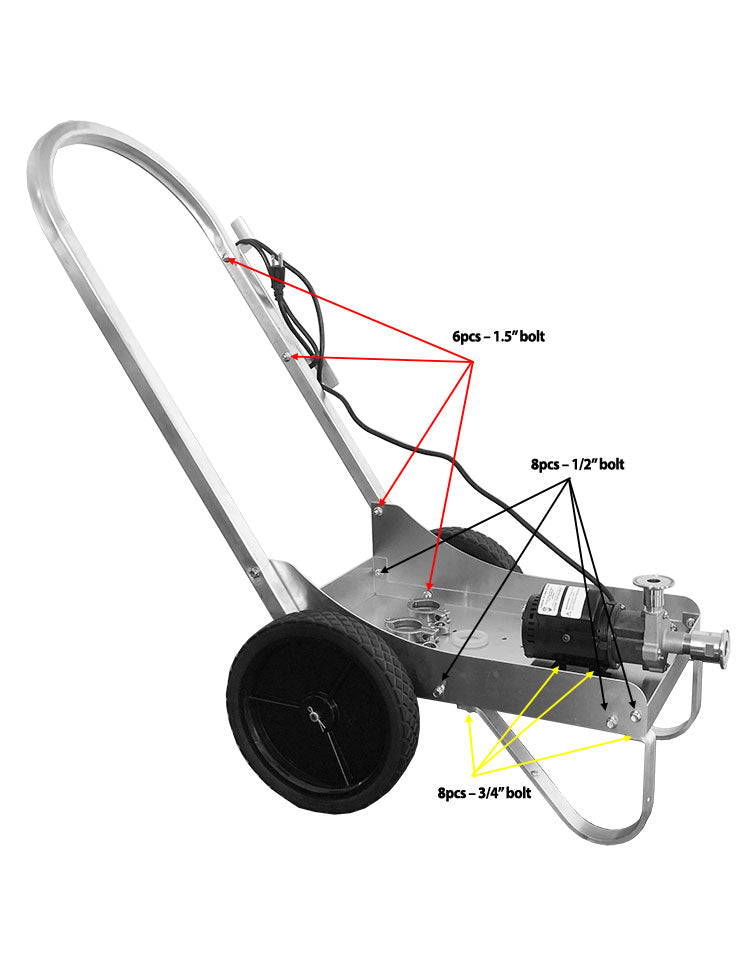

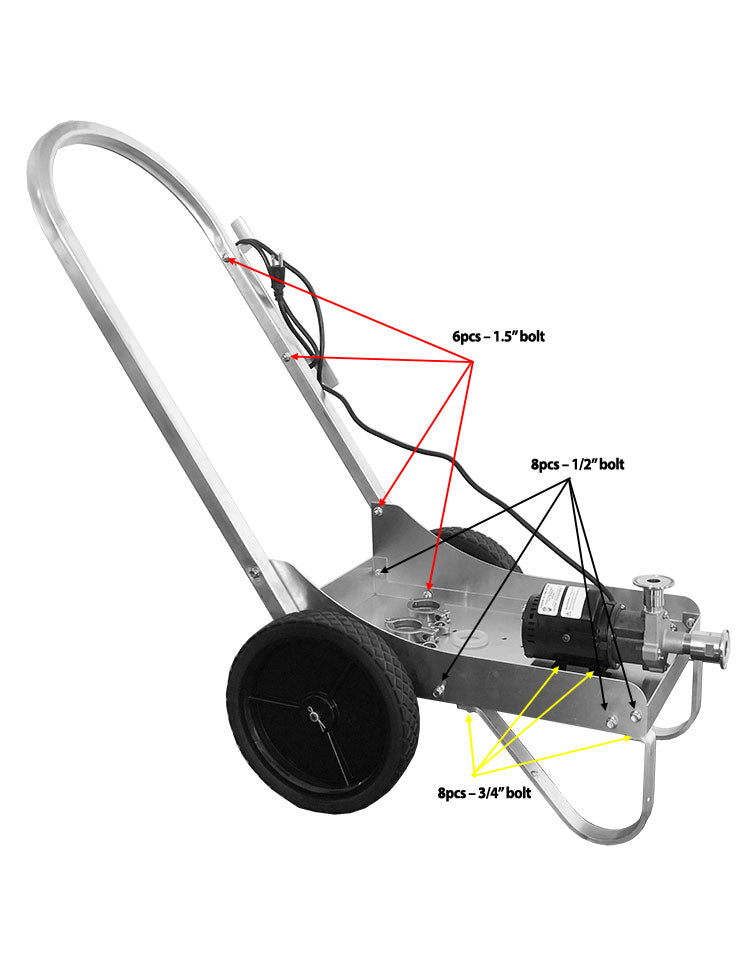

Additional accessories can be added such as hoses (5' of 0.5"ID and 2' of 0.75"ID food-grade, high-temp, heavy-duty, high-pressure, braided silicone tube, two 1.5" TC (tri-clamp) clamps, two 1.5" TC silicone gaskets, one 3/4" FPT x 1.5"TC fitting and one 1/2 FPT x 1.5" TC fitting) or hoses and pump cart.

Note: do NOT operate these pumps dry. Water should always be unrestricted and free flowing into the pump through a 3/4" or greater diameter hose.

Note: these March magnetic drive beer pumps are non-self-priming magnetic drive units built specifically to handle hot wort and water. They do not require a mechanical seal between moving parts (which greatly improves reliability) but they are not self-priming (meaning they need to be full of liquid to operate) and they require liquid being pumped to lubricate the internal parts. If the pump is run dry for a period of time the impeller and shaft may become damaged. The port and 3/4" (or 1") line leading to the pumps should always be fully open and it is best to never fully close the exit port on the pump when operating, as the free flow of liquid serves to ensure the pump head (impeller shaft) does not overheat. To regulate the flow only use a valve on the discharge/outlet side of the pump (either on the exit port of the pump, or the port where liquid is being returned to the brewing system from the pump.

For details on Proposition 65 (California residents) see March's website.

BREWinfo: Installing the brewery pump hoses and fittings

BREWinfo: March beer pumps spec sheet

Troubleshooting the March 815 beer pump

March Pump Troubleshooting Guide

Share

Pump works great, fast shipping. Always a pleasure dealing with Nathan!