Articles on brewing equipment, how to brew beer and open a brewery

Installing a Portable Fermentation Temperature ...

For most styles of beer, a chilling system is important for producing a great tasting beverage. In fact, aside from proper sanitation, temperature control is arguably the single most important criteria for...

Installing a Portable Fermentation Temperature ...

For most styles of beer, a chilling system is important for producing a great tasting beverage. In fact, aside from proper sanitation, temperature control is arguably the single most important criteria for...

Preventing Scorched Wort and Burnt Flavor in Yo...

After four weeks of eager anticipation, there are few things more devastating to a brewer than discovering an unwanted microbial infection or tasting burnt/smokey notes in your latest brew. The BIAC...

Preventing Scorched Wort and Burnt Flavor in Yo...

After four weeks of eager anticipation, there are few things more devastating to a brewer than discovering an unwanted microbial infection or tasting burnt/smokey notes in your latest brew. The BIAC...

How to Resurrect Yeast and Keep Fermentation Alive

Most brewers have had the unhappy experience where fermentation is proceeding along nicely, then quite suddenly and unexpectedly stops shy of the target gravity. In a panic, the fermenter lid is...

How to Resurrect Yeast and Keep Fermentation Alive

Most brewers have had the unhappy experience where fermentation is proceeding along nicely, then quite suddenly and unexpectedly stops shy of the target gravity. In a panic, the fermenter lid is...

Maintaining Low Fermentation Temperatures Witho...

Controlling temperature during fermentation is very important for best flavor and batch-to-batch consistency. Most often, home brewers have controlled fermentation temperatures by regulating the room temperature or placing their fermenter in an...

Maintaining Low Fermentation Temperatures Witho...

Controlling temperature during fermentation is very important for best flavor and batch-to-batch consistency. Most often, home brewers have controlled fermentation temperatures by regulating the room temperature or placing their fermenter in an...

Operating the 240V/30amp Brewing Power Controller

The 240V Brewing Power Controller (BPC) is designed to give safe and easy access to 240V/30amp power in the home. Without it, one would either have to use 120V power or...

Operating the 240V/30amp Brewing Power Controller

The 240V Brewing Power Controller (BPC) is designed to give safe and easy access to 240V/30amp power in the home. Without it, one would either have to use 120V power or...

Controlling fermentation temperature

Regulating the temperature in your fermenter (3-in-1 or 4-in-1) is critical in order to obtain consistency from batch to batch and produce results that match the style of beer. If the...

Controlling fermentation temperature

Regulating the temperature in your fermenter (3-in-1 or 4-in-1) is critical in order to obtain consistency from batch to batch and produce results that match the style of beer. If the...

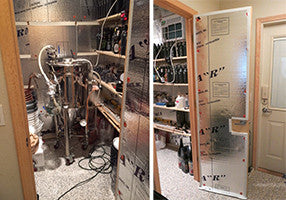

How to Build a Temperature-Controlled Closet or...

Precise temperature control during fermentation is a critical aspect of brewing high quality beer but it can be challenging to achieve, especially in warm climates where cold tap water is not available. BREWHA's...

How to Build a Temperature-Controlled Closet or...

Precise temperature control during fermentation is a critical aspect of brewing high quality beer but it can be challenging to achieve, especially in warm climates where cold tap water is not available. BREWHA's...

See next page for more articles on brewing equipment, how to brew beer and open a brewery