Every hose and tank is designed with a maximum allowable working pressure (MAWP), which if exceeded, will cause damage and could even pose a safety hazard. The BREWHA tank jackets have been designed to hold up to 5psi of pressure (7psi in the 4-in-1 conical fermentors) which is more than enough pressure to allow adequate flow rates for chilling wort and maintaining temperature during fermentation.

In many regions, municipal water is a cost-effective source of chillant. Ground, river or lake water is often delivered at temperatures below what is necessary for pitching yeast so it provides a much less costly source of chilled water than an electric chiller is able to provide. And where municipal water temperature is higher than what is necessary for yeast, a combination of municipal water (to perform the lion’s share of the cooling) before switching to electrically chilled water can be a cost-effective way to chill.

Municipal water, however, is often supplied at pressures above 75psi, so if it is fed directly into the jacket of a vessel, it could cause pressure inside the jacket to quickly rise above the MAWP, damaging the vessel. (Large tanks designed to hold 75psi require ¼” steel which makes them very heavy, and very expensive.)

To ensure that pressure doesn’t rise above the allowable limit when using municipal water (brewery pumps can provide high pressure water too so caution is needed with them as well) never throttle or restrict the exit flow in any way, and a water pressure regulator should be installed on the feed line, prior to the vessel. The ¼” BREWHA Water Pressure Regulator (which supplies approx 10L/min) is excellent for maintaining fermentation temperature, or for chilling post boil in the smaller tanks (up to 1.5BBL). For chilling where a higher volume of chilling water is needed for more rapid chilling, such as when chilling wort post boil in the 3 and 5BBL 4-in-1s, a ½” or ¾” regulator on the brewery water lines is more appropriate.

Occasionally the pressure gauge in the regulator may get plugged with sediment from your water source, or a part need to be replaced. Follow these instructions to reassemble the regulator.

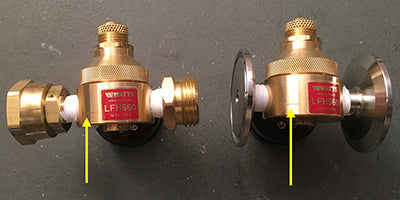

| 1. The BREWHA Water Pressure Regulator is comprised of a main body, a pressure gauge and either garden hose or 1.5" sanitary/tri-clamp compatible connections. |  |

|

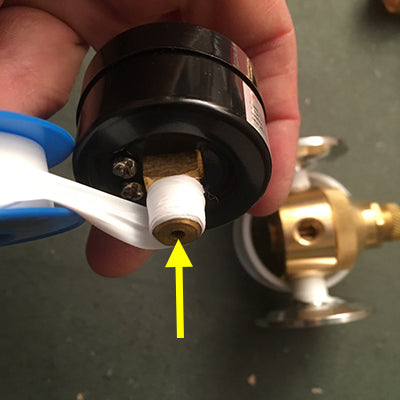

2. If fouling inside the regulator is suspected of impeding proper functioning, it can be inspected by removing the top cap |

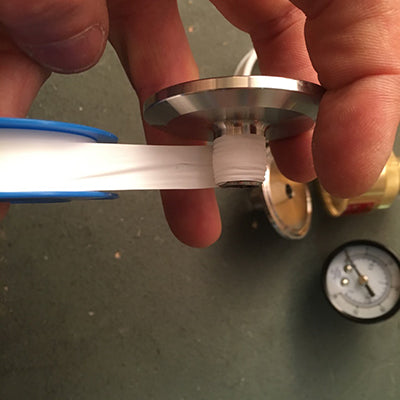

| 3. Inspect the gauge entry to ensure it is not packed with sediment and impeding gauge readings. When reinstalling the gauge, apply food safe pipe sealant or teflon tape. Applying teflon tape in a clockwise direction will ensure the tape is not unwound when tightening. |  |

|

4. Tape nipples in the same clockwise direction. |

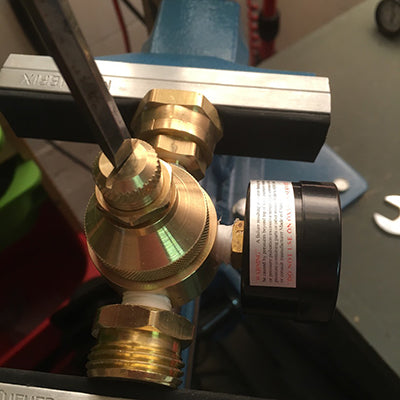

| 5. Secure fittings to the regulator. |  |

|

6. Secure 0-25psi pressure gauge to the regulator. |

| 7. Turn screw out (counter-clockwise) to reduce pressure, and in (clockwise) to increase pressure. To test the pressure setting, connect the upstream side of the regulator to your water source, and connect a valve to the downstream side of the regulator with the valve opened very slightly to let air bleed out. Don't open the valve too wide as the water flow rate into the regulator needs to exceed the flow rate out so that back pressure builds up inside the valve. Place the exit side of the valve over a sink then turn the water source on. After the air exits the regulator, the dial on the regulator will show what pressure it is permitting and can be adjusted as necessary. |  |

|

8. Tighten nut to secure pressure adjusting screw. |

| 9. Ensure water will flow in the direction of the arrow on the regulator. |  |

|

10. For testing the pressure, connect a water source to the inlet side, and a valve to the outlet side. Open the valve very slightly so that air trapped inside the regulator can escape and a small stream of water can leave the regulator (to ensure delayed regulator response does not give a false reading). Adjust the regulator to about 5psi; when the valve is fully opened, the pressure will drop to 0psi, when the valve is closed it may spike to about 7psi. |

Click here for the Water Pressure Regulator product page

1 comment

Great Post